Mercury Bravo 1 XC Pro Finished Propeller

The Mercury Racing Pro Finished Bravo I XC Propeller, designed specifically for single outboard powered hulls, features a tremendous amount of blade cup. Ideal for shallow water running Flats Boats. The enhanced cup enables the engine to be run at elevated transom heights – without sacrificing performance. The larger blade area enables the prop to stay hooked up for quick planing and enhanced performance throughout the engine rpm range. The exhaust tube is designed to support planing and stability at lower speeds. The Bravo I XC outperformed many four blade offerings with shorter time to plane, improved grip at lower speeds and quicker throttle response.

- Hub kit is sold separately. Please see the fitment information provided to select the correct hub kit for your application.

- Enabled with 4-hole Performance Vent System (PVS) to allow optimal hole-shot customization.

Important Note:

- According to the Mercury propeller guide handbook the added cup reduces rpm, plan to drop 2" of pitch compared to standard Bravo 1. Also, if running a jack plate consider increased engine height.

Mercury Marine offers a 1-year limited warranty on all Mercury propellers. To determine warranty requirements for a specific item, please contact the manufacturer or contact us for assistance. Please note warranty processing may take 2-4 weeks and will be subject to Mercury Marine's policies and discretion. Mercury warranty does not cover defects determined to be caused by normal wear or due to customer negligence.

Call us at (920) 788-0220 during our standard business hours to talk to an expert. Or send us a message (average reply time 2h).

Description

Mercury Marine Bravo 1 XC Propeller

The Mercury Racing Pro Finished Bravo I XC Propeller, designed specifically for single outboard powered hulls, features a tremendous amount of blade cup. Ideal for shallow water running Flats Boats. The enhanced cup enables the engine to be run at elevated transom heights – without sacrificing performance. The larger blade area enables the prop to stay hooked up for quick planing and enhanced performance throughout the engine rpm range. The exhaust tube is designed to support planing and stability at lower speeds. The Bravo I XC outperformed many four blade offerings with shorter time to plane, improved grip at lower speeds and quicker throttle response.

- Hub kit is sold separately. Please see the fitment information provided to select the correct hub kit for your application.

- Enabled with 4-hole Performance Vent System (PVS) to allow optimal hole-shot customization.

Important Note:

- According to the Mercury propeller guide handbook the added cup reduces rpm, plan to drop 2" of pitch compared to standard Bravo 1. Also, if running a jack plate consider increased engine height.

Mercury Marine Bravo 1 XC Propeller

Right-Hand Rotation (Clockwise)

Stainless Steel

Through hub exhaust with Mercury's Performance Vent System (PVS).

Mercury Flo-Torq Hub Kit (sold separately). Please see the fitment information below to determine which hub kit is needed for your application.

Will this propeller fit my motor?

Bravo 1 XC Propeller Fitment

The Mercury Marine Bravo 1 XC propeller requires a Flo-Torq hub kit for installation (sold separately). Listed below are the models of Mercury Marine outboards/sterndrives that the Bravo 1 XC propeller will fit, along with the corresponding hub kit necessary for installation.

Mercury 90 - 115 Command Thrust Outboards (15-Tooth Spline)

Mercury 135 - 400 HP Outboards

Mercury Mercruiser Alpha & Bravo One Sterndrives

Non-Mercury Outboards (4.75" Gearcase)

Mercury Bravo 1 XC Blog

Mercury Bravo 1 XC Propeller

Unleashing performance in shallow water

The Mercury Bravo 1 XC propeller features an extra-cupped design—with nearly 30% more cupping along its trailing edge—ensuring superior engine hook-up and extended prop life by acting as a sacrificial anode. Designed for shallow water applications like the Gulf of America, it boasts a generous blade area and an optimized exhaust tube for rapid planing, improved low-speed grip, and enhanced throttle response. Tested with Simmons Custom Boats, the Bravo 1 XC often outperforms four-blade propellers, offering significant durability and performance advantages even in waters less than 2 feet deep.

Important: According to the Mercury Propeller Guide handbook it is recommended to drop 2" of pitch compared to standard Bravo 1 propellers. This adjustment will need to be made because the added cupping will reduce max RPMs. Also, if running a jack plate you may want to consider running at an increased engine height.

If you have any questions about pitch selection please feel free to contact us.

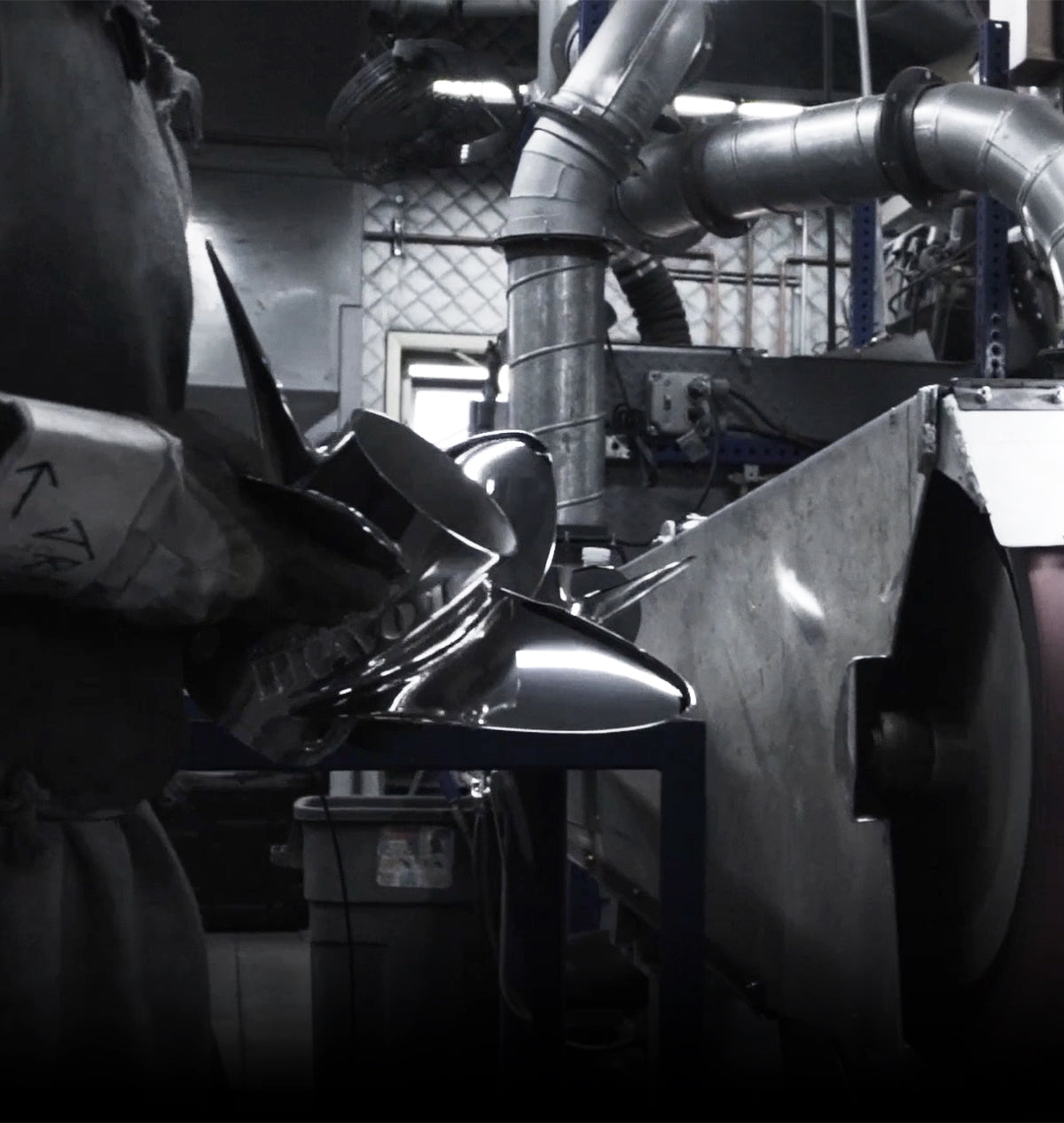

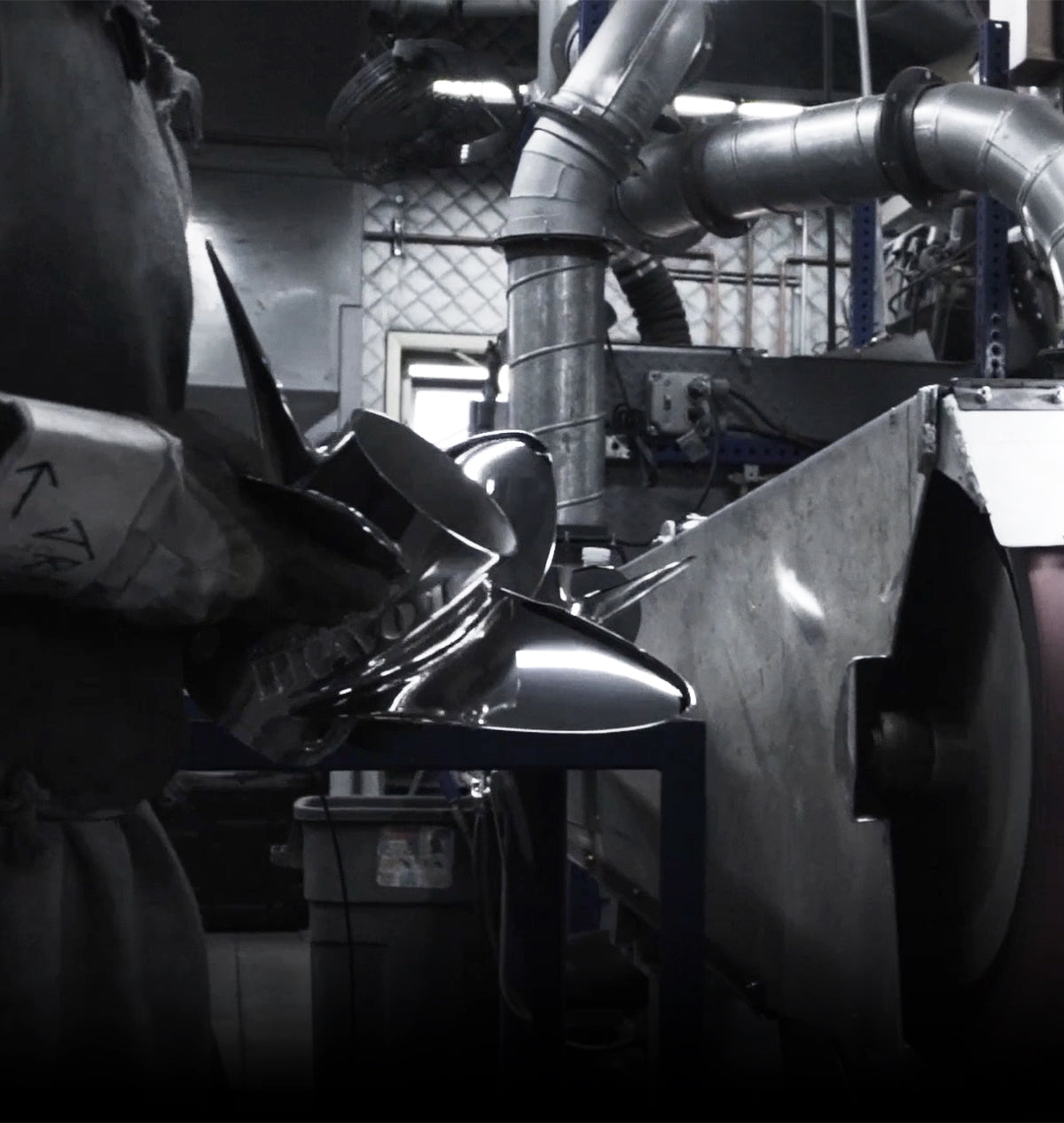

During the Pro Finish process, the leading edges of the propeller are precisely thinned—though not to the extent of a Lab Finish—while the cup heights are meticulously blueprinted to ensure optimal performance. Each propeller is then carefully zero-balanced by hand, guaranteeing exceptional smoothness and precision.

Important: According to the Mercury Propeller Guide handbook it is recommended to drop 2" of pitch compared to standard Bravo 1 propellers. This adjustment will need to be made because the added cupping will reduce max RPMs. Also, if running a jack plate you may want to consider running at an increased engine height.

If you have any questions about pitch selection please feel free to contact us.

During the Pro Finish process, the leading edges of the propeller are precisely thinned—though not to the extent of a Lab Finish—while the cup heights are meticulously blueprinted to ensure optimal performance. Each propeller is then carefully zero-balanced by hand, guaranteeing exceptional smoothness and precision.

Expert Advice

Do you need guidance in selecting the correct Mercury Marine Bravo 1 XC propeller for your application? Contact Boat Prop Warehouse today to talk to an expert.

Prop School

Do you have questions about the basics of propellers? Check out our comprehensive guide on the different facets of propeller technology, and its impact on boat performance.

Expert Advice

Do you need guidance in selecting the correct Mercury Marine Bravo 1 XC propeller for your application? Contact Boat Prop Warehouse today to talk to an expert.

Prop School

Do you have questions about the basics of propellers? Check out our comprehensive guide on the different facets of propeller technology, and its impact on boat performance.

Testimonials

Landry S.

Mercury Bravo 1 XC Propeller

Running the Bravo 1 XC on a Majek 24 Reaper and the performance is unbeatable. The boat gets on plane IMMEDIATELY and the holding exceptional.

Joel B.

Mercury Bravo 1 XC Propeller

I switched for the Rev 4 to the Bravo 1 XC propeller on my Shoalwater and it is night and day difference. With the XC propeller the hole-shot is amazing. Still waiting yet to run it more to see how long it last.

Devon H.

Mercury Bravo 1 XC Propeller

This is the best prop for shallow water running period. I've fished the gulf my whole life and tried several different props but this one is the best.

Marcus F.

Mercury Bravo 1 XC Propeller

I was recommended the Bravo 1 XC by Nick at Mercury. The new prop does exactly what he said it would. We lost a bit of top end speed, but that was expected. I'd rather have the boat jump out of the water.

Aaron H.

Mercury Bravo 1 XC Propeller

Running a Mercury 300HP on my Simmons Revolution 25 and the performance is amazing. The boat came from Simmons with the Bravo 1 XC already I was just getting another as a spare. So I know it works well already.

Carsen E.

Mercury Bravo 1 XC Propeller

I lost probably 3-4 MPH on the top end with the Bravo 1 XC installed on my Shoalwater Boat. The hole-shot is great and the handling is much better, the nose stays down when planing which helps.

Shop All

Mercury Propellers

Whether you’re looking for a replacement prop or want to optimize your boat’s speed, hole shot or efficiency, keep in mind that prop selection is about more than just pitch, diameter and number of blades. Performance is influenced by every aspect of a prop’s geometry, right down to cup, rake angle and edge shape.

Aluminum

Racing

Contact Us

Do you have any questions?

We are here to help! You can contact us either by our online form on this page or via phone, email, or chat.

Important Note: The more information you can provide us with, the more accurate/reliable any propeller suggestions we make will be.